Perhaps this scenario is familiar to you?

- Engineer A brings back a faulty Hard Disk from a client site and dumps it in your Workshop.

- Engineer B walks into your Workshop looking for a Hard Drive to take to a client site. Picks up the faulty HDD Engineer A left behind.

- Engineer B visits client site. Realises Hard Drive is faulty. Takes faulty Hard Disk back and dumps it in your Workshop.

- Engineer C walks into your Workshop looking for a a Hard Drive to take to a client site. Picks up the faulty HDD Engineer A and B left behind…

… and so on.

If the above scenario is familiar to you then here is the simple workshop tip that may save your MSP a fortune!

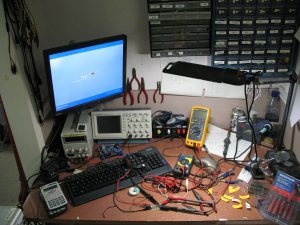

Saving Time and Money in the Workshop

Whenever your engineers bring a piece of equipment back from a client site, they should follow a simple process:-

Update your Professional Services Automation (PSA) or Helpdesk ticket to note the make/model of the equipment that has been brought back to the workshop, and why it has been brought back – this might be for further testing, data recovery or even disposal.

Label the piece of equipment with the PSA or Helpdesk ticket number, client name and issue. For instance “1004 – ABC Widget Co – No power to HDD”.

Simple! The next time an engineer walks into your workshop looking for a working piece of equipment, they’ll know not to pick up anything that is labelled.

Using Under Repair and Disposals Areas

In my own Managed Service Provider (MSP) business, we took the idea a step further and specifically had two areas of our Workshop clearly highlighted as an “Under Repair” section and a “Disposals” section.

Simply put, if a piece of equipment needed further testing and/or a repair – it was labelled using the above process and then placed in the “Under Repair” area.

If the equipment had been tested and was either dead or beyond viable economic repair – it was labelled using the above process and then placed in the “Disposals” area.

By utilising this process you can also free up your Senior Engineers time by assigning a Junior member of team to deal with hardware testing and disposals. Your Junior engineer gains valuable knowledge troubleshooting hardware, and your Senior engineer can concentrate on more important work.

I’ve written before about how to ethically dispose of IT equipment and once you have this process in place, it becomes much easier and cost effective to be ethical and environmentally friendly about disposals too.

Conclusion

If you have ever walked into your workshop and shuddered at the kit piled high and gathering dust, then you’re probably keenly aware of the time and money your engineers are wasting by dumping kit there.

Rather than flush money away by continuously dumping equipment for other members of the team to at best – scratch their heads wondering over, and at worst – erroneously try to re-use wasting both their time and yours – invest in a label printer and insist that any kit brought back from client sites is documented within a ticket, labelled and placed in the correct area.

It’s the simple workshop tip that may save your MSP a fortune!

photo credit: jamesbastow via photopin cc

Comments

4 thoughts on The Simple Workshop Tip That May Save Your MSP a Fortune

CRAIG SHARP

16TH JULY 2014 16:04:36

Hmmm, I have to be honest here Richard and say that the whole idea of taking hard disks from site to repair / replace, or repairing old PC hardware in general is rather 2004 in my opinion. We supply hardware with 3 year manufacturer warranty and if failures occur then the hardware is repaired by a visiting (HP) engineer - if clients have old hardware that's failing or failed then its an opportunity to provide replacements. An example would be a client who recently asked "can you repair my faulty laptop screen" ? It was a laptop with poor specification, provided by a previous IT provider in early 2011 (so 3.5 years old) and the client was advised "sorry, we can;t offer laptop repairs of that nature, but it looks like a good time to get that replaced with a better model" - a few days later an order for a new laptop was raised. Hardware is very reliable if you buy well - we all have our favorites but Dell, HP or similar will last 3-4 years with little likelihood of a hardware failure - after that point its time to renew, not repair !

RICHARD TUBB

17TH JULY 2014 09:06:24

Craig - I agree, I'd suggest MSP's advise their clients to have Hardware Warranty's on all equipment they use and so the need for hardware repairs is diminishing. With that said, the reality is that many IT companies do make hardware repairs for their clients and even more dispose of equipment on behalf of their clients. In these scenarios, kit inevitably ends up being brought back to the Workshop and even if it is just for disposal - failing to label it as such can lead to time wasted re-testing equipment.

BRANDON PHIPPS

18TH JULY 2014 15:47:46

We collect old equipment all the time. Sometimes I use it to build PC's for a local charity that donates them to to families with children in school that need the computer to complete their homework. Sometimes we use them as Spiceworks / Splunk servers to improve the monitoring service offered to the clients. Every now and then the equipment is in a decent enough condition to refurbish and set aside as a client "loaner" PC while equipment is being replace or repaired. Once a year we clean house and send whatever isn't useful or worth it to a local recycling facility.

RICHARD TUBB

18TH JULY 2014 20:26:47

Brandon - great to hear you actively look to reuse equipment for such great causes. Keep up the good work!